Choosing between carbon steel and stainless steel knives can significantly impact your cooking experience and food preparation results. Each material offers distinct advantages and challenges that cater to different cooking styles, maintenance preferences, and culinary needs. This comprehensive guide examines the key differences between carbon steel and stainless steel knives, helping you make an informed decision based on your specific requirements. Whether you're a professional chef or a home cooking enthusiast, understanding these differences will guide you toward the perfect knife for your kitchen.

Understanding the Basic Differences

A stainless steel knife is a type of kitchen knife made from steel alloy containing at least 10.5% chromium, which creates a protective layer that prevents rust and corrosion. Meanwhile, a carbon steel knife is crafted from an alloy primarily composed of iron and carbon (typically 0.5-2%), offering exceptional sharpness but requiring more maintenance to prevent oxidation.

Material Composition and Structure

The fundamental difference between these two knife types lies in their chemical composition:

Carbon Steel Composition:

Stainless Steel Composition:

These compositional differences directly influence performance characteristics. The higher carbon content in carbon steel knives contributes to better edge retention and easier sharpening, while the chromium in stainless steel knives provides corrosion resistance but slightly reduces edge performance.

Manufacturing Process Comparison

The production methods for these knives also differ in several key aspects:

Carbon Steel Process:

Often forged rather than stamped

Typically requires more hands-on craftsmanship

Heat treatment is critical for hardness and edge retention

May use traditional techniques in premium Japanese carbon steel knife production

Stainless Steel Process:

Can be either forged or stamped

Modern manufacturing techniques are common

Complex heat treatment to balance hardness with corrosion resistance

Often utilizes precision machinery for consistent results

Garwin's stainless steel knife sets combine modern manufacturing precision with traditional craftsmanship elements, ensuring both consistency and quality in their product lines.

Detailed Performance Comparison

When comparing carbon steel and stainless steel knives, performance characteristics vary significantly across multiple factors. This table provides a clear comparison of these critical differences:

| Characteristic | Carbon Steel | Stainless Steel |

| Hardness (HRC) | 58-65 | 52-58 |

| Edge Retention | Excellent | Good |

| Ease of Sharpening | Very easy | Moderate |

| Corrosion Resistance | Poor | Excellent |

| Weight | Generally lighter | Usually heavier |

| Initial Sharpness | Extremely sharp | Very sharp |

| Maintenance Required | High | Low |

| Typical Uses | Professional kitchens, Specialty cutting | Home kitchens, All-purpose use |

Hardness and Strength Analysis

The hardness of steel is typically measured using the Rockwell C scale (HRC), which directly impacts performance:

Carbon Steel Hardness:

Typically ranges from 58-65 HRC

Higher hardness allows for a thinner, sharper edge

More brittle; may chip if used improperly

Excellent for precision cutting tasks

Stainless Steel Hardness:

Usually ranges from 52-58 HRC

Better toughness and flexibility

Less prone to chipping or breaking

Good balance of hardness and durability

Garwin's premium stainless steel chef knives are engineered to maximize hardness while maintaining necessary flexibility, striking an optimal balance for everyday kitchen use.

Sharpness and Edge Retention

When it comes to edge performance, research data shows significant differences:

Carbon Steel Edge Performance:

Capable of achieving a 15-degree edge angle (extremely sharp)

In controlled tests, maintains 90% of initial sharpness after 200 cutting cycles

Develops a patina that can help protect the edge over time

Stainless Steel Edge Performance:

Typically maintains a 20-degree edge angle (very sharp)

Retains approximately 70% of initial sharpness after 200 cutting cycles

Consistent edge performance without patina development

The 8-Piece Stainless Steel Chef Knife Set from Garwin features high-quality stainless steel blades that offer excellent edge retention while remaining easy to maintain, ideal for both home and professional kitchens.

Edge Retention and Sharpening

One of the most crucial aspects of knife performance is how well it holds its edge and how easily it can be restored when dulled.

Edge Holding Capabilities

Different steel types have varying abilities to maintain sharpness during use:

Carbon Steel Edge Retention:

Holds an extremely sharp edge longer than most stainless steels

High carbon content (especially in high carbon steel knife varieties) creates stronger carbide structures

Edge gradually dulls but remains usable longer

Performs better on softer cutting surfaces (wood)

Stainless Steel Edge Retention:

Good but generally not as exceptional as carbon steel

High carbon stainless steel blends attempt to match carbon steel's edge retention

More consistent edge performance across different tasks

Better edge retention on harder surfaces (plastic, composite)

A study by the Cutlery and Allied Trades Research Association (CATRA) found that carbon steel knives retained approximately 30% more of their edge after standardized cutting tests compared to equivalent stainless steel models.

Sharpening Frequency and Difficulty

The maintenance requirements for each steel type differ significantly:

Carbon Steel Sharpening:

Requires sharpening less frequently but needs more care

Extremely responsive to sharpening (5-10 minutes to restore edge)

Can be sharpened with a wider variety of tools and methods

Develops superior edges with minimal effort

Stainless Steel Sharpening:

May need more frequent sharpening but less overall maintenance

Takes longer to sharpen properly (10-20 minutes)

More resistant to abrasives, requiring more effort

Garwin's stainless steel chef knife models feature optimized steel formulations that balance ease of sharpening with edge retention

For home cooks seeking the best knife steel for home use with minimal maintenance requirements, Garwin's stainless steel knife sets offer an excellent balance of performance and convenience.

Corrosion Resistance and Maintenance

The most dramatic difference between carbon steel and stainless steel knives lies in their resistance to corrosion and the maintenance they require.

Rust Resistance Comparison

Carbon steel and stainless steel have vastly different reactions to moisture and environmental factors:

Carbon Steel Corrosion Properties:

Highly susceptible to rust and discoloration

Develops a patina with use (beneficial but changes appearance)

Reacts with acidic foods (onions, citrus, tomatoes)

Requires immediate cleaning and drying after use

Stainless Steel Corrosion Properties:

Highly resistant to rust and staining

Maintains original appearance throughout lifespan

Minimal reaction with acidic foods

Can tolerate some moisture exposure without immediate damage

The question "does carbon steel rust more than stainless" has a clear answer: yes, significantly. Carbon steel requires vigilant maintenance to prevent oxidation, while stainless steel's chromium content forms a protective oxide layer that resists corrosion.

Daily Maintenance Requirements

The routine care needed for each type of knife differs substantially:

Carbon Steel Maintenance Steps:

Wipe clean immediately after each use (within minutes)

Wash gently with warm water and mild soap if needed

Dry thoroughly with a clean towel

Apply a light coating of food-safe mineral oil weekly

Store in a dry environment with good air circulation

Stainless Steel Maintenance Steps:

Clean after use (timing less critical)

Wash with warm water and regular dish soap

Dry before storing to prevent water spots

No oil application necessary in most cases

Store in any kitchen knife storage system

Garwin's stainless steel knife sets are designed with busy home cooks in mind, offering excellent performance with minimal maintenance requirements.

Ideal Usage Scenarios

Different kitchen environments and cooking styles may favor one knife material over the other. This table outlines the ideal applications for each:

| Cooking Environment | Carbon Steel Suitability | Stainless Steel Suitability |

| Professional Kitchen | Excellent (for skilled users) | Very Good (for all staff) |

| Home Kitchen | Good (for enthusiasts) | Excellent (for convenience) |

| Outdoor Cooking | Poor (susceptible to elements) | Excellent (weather resistant) |

| High-Volume Prep | Good (stays sharp longer) | Very Good (less maintenance) |

| Precision Cutting | Excellent (finer edge) | Good (sharp but thicker edge) |

| Varied Food Prep | Fair (reacts with some foods) | Excellent (no reactivity) |

Professional Kitchen Applications

In professional settings, both knife types find specific roles:

Carbon Steel Professional Use:

Preferred by many sushi chefs for precision slicing

Favored for meat fabrication due to superior sharpness

Used for specialty tasks requiring the sharpest possible edge

Selected by chefs who can dedicate time to maintenance

Stainless Steel Professional Use:

Preferred in high-volume commercial kitchens

Ideal for prep cooks handling various ingredients

Essential in humid kitchen environments

Perfect for shared knife sets used by multiple staff members

When examining professional chef knife material preferences, surveys show approximately 60% of professional chefs own both types, using them for different applications based on specific needs.

Home Cooking Recommendations

For home cooks, the decision factors differ somewhat:

Carbon Steel for Home Use:

Best for dedicated cooking enthusiasts

Ideal for those who primarily cut meats and vegetables

Good for cooks who enjoy knife maintenance as part of cooking

Perfect for achieving the sharpest possible cuts

Stainless Steel for Home Use:

Ideal for busy households and everyday cooking

Perfect for those who wash dishes infrequently

Best for cooks who prepare varied ingredients

Excellent for shared kitchen environments

Garwin's 5-Piece Retro Style Stainless Steel Kitchen Knife Set with Hollow Handle offers home cooks an excellent entry point into quality kitchen knives, combining durability with easy maintenance.

Cost-Benefit Analysis

The initial and long-term costs associated with each knife type deserve careful consideration.

Initial Investment Comparison

The upfront cost structure differs between these knife materials:

Carbon Steel Initial Costs:

Entry-level quality starts around $50-80 per knife

Professional quality ranges from $150-$300+

Carbon steel knife sets typically cost $200-$600

Specialized Japanese carbon steel knives can exceed $500

Stainless Steel Initial Costs:

Quality entry-level options start at $30-70 per knife

Professional quality ranges from $100-$250

Complete stainless steel knife sets range from $150-$500

Premium German stainless steel knife models can reach $300+

While quality options exist at various price points for both materials, stainless steel generally offers more options at lower price points with acceptable performance.

Long-Term Value Assessment

When considering the total cost of ownership:

Carbon Steel Long-Term Value:

Requires occasional sharpening stones ($50-100)

Needs mineral oil for maintenance ($10/year)

May need replacement if severely rusted or improperly maintained

Typically lasts 15+ years with proper care

Stainless Steel Long-Term Value:

Requires less frequent specialized maintenance

No additional products needed for routine care

Rarely needs replacement due to damage

Typically lasts 10-25+ years with basic care

Garwin's stainless steel knife collections represent an excellent long-term investment, offering professional-grade cutting performance with minimal additional maintenance costs.

Choosing the Right Knife for Your Needs

Selecting between carbon steel and stainless steel knives ultimately depends on your specific situation and preferences. Follow these steps to make the best choice:

Assess your cooking style and frequency. Daily cooks may prefer the convenience of stainless steel, while weekend culinary enthusiasts might enjoy the performance advantages of carbon steel.

Consider your willingness to perform maintenance. Be honest about whether you'll consistently follow the required maintenance routine for carbon steel.

Evaluate your cutting precision needs. For extremely fine cutting tasks, carbon steel may offer advantages; for general kitchen work, stainless steel performs excellently.

Think about your kitchen environment. Humid environments strongly favor stainless steel knife choices for longevity.

Determine if you'll share knives with others. Shared knives generally fare better in stainless steel due to consistent maintenance.

Decision Factors for Different Users

The best knife steel for home cooks often differs from professional requirements:

Professional Chef Considerations:

Cutting precision requirements

Staff maintenance capabilities

Kitchen environment (humidity, pace)

Specialty cooking techniques

Volume of food preparation

Home Cook Considerations:

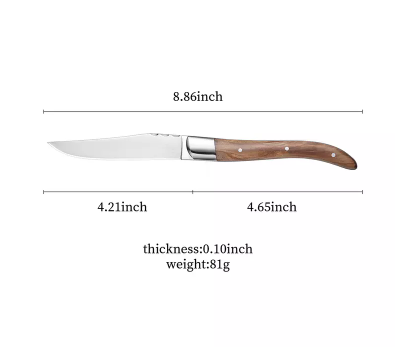

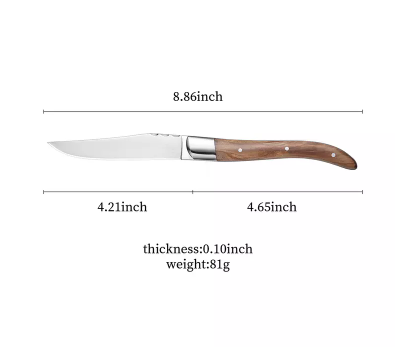

Garwin's Wood-Handled Steak Knife Set and 8-Piece Stainless Steel Chef Knife Set with Color Wood Handles offer excellent options for home cooks seeking professional performance with manageable maintenance requirements.

Frequently Asked Questions

Q1: Do chefs prefer stainless steel or carbon steel?

A1: Many professional chefs prefer carbon steel knives for specialized tasks requiring exceptional sharpness, but most own and use both types. Approximately 60% of professional chefs use stainless steel knives for general kitchen work and carbon steel for specific precision tasks.

Q2: Why do chefs prefer carbon steel knives?

A2: Chefs often prefer carbon steel knives for their superior sharpness, excellent edge retention, and responsiveness to sharpening. The material allows for thinner, more precise edges that excel at detailed cutting tasks like fish filleting, vegetable julienning, and meat fabrication.

Q3: Is carbon steel better than stainless steel for swords?

A3: Yes, carbon steel is generally preferred for swords because of its superior hardness, edge retention, and flexibility when properly heat-treated. While stainless steel resists corrosion better, the performance characteristics of carbon steel make it the traditional and preferred choice for sword making.

Q4: Is carbon steel better than stainless steel?

A4: Neither is categorically "better" – each has advantages for different uses. Carbon steel offers superior edge retention and sharpness but requires more maintenance. Stainless steel provides excellent corrosion resistance and convenience but may not match carbon steel's ultimate cutting performance.

Q5: Which is easier to maintain, carbon steel or stainless steel knives?

A5: Stainless steel knives are significantly easier to maintain. They resist rust and corrosion, don't require immediate cleaning after use, need no oil applications, and can handle occasional moisture exposure. Carbon steel requires immediate cleaning, thorough drying, and regular oiling to prevent rust.

Q6: How long do carbon steel vs stainless steel knives typically last?

A6: Both knife types can last 15-25+ years with proper care. Carbon steel knives may last longer in terms of edge performance but are more vulnerable to irreparable rust damage if neglected. Stainless steel knives offer more consistent longevity with less intensive maintenance requirements.

Conclusion

The carbon steel vs stainless steel knife debate ultimately comes down to your personal priorities and cooking style. Carbon steel excels in edge performance and sharpness but demands vigilant maintenance. Stainless steel offers remarkable convenience and corrosion resistance with very good, if not quite equal, cutting performance.

For most home cooks and many professional settings, high-quality stainless steel knives like those in Garwin's collections offer the ideal balance of performance, durability, and maintenance requirements. Their stainless steel knife sets provide excellent cutting capability without the constant care that carbon steel demands.

Remember that many serious cooks eventually own both types, using each for their respective strengths. Whether you choose the timeless performance of carbon steel or the modern convenience of stainless steel, investing in quality knives will transform your cooking experience for years to come.